We offer a wide variety of 3D printing materials for your additive manufacturing needs, including FDM, Polyjet, Stereolithography and Multi-jet Fusion materials.

Providing Stratasys-brand items for our FDM materials, you will receive high-quality, high-strength products capable of translucency, suitable for outdoor applications and even parts that can withstand functional testing.

We are constantly adding new material options if they offer additional benefits or cost savings we can pass on to our clients. We currently work with the following FDM materials:

- ANTERO 800NA

- ABS-M30

- ABS-M30i

- ABSplus

- ABSi

- ASA

- FDM Nylon 6

- FDM Nylon 12CF

- FDM Nylon 12

- FDM TPU 92A

- PC

- PC-ABS

- PPSF

- STS-130

- ULTEM 1010 Resin

- ULTEM 9085 Resin

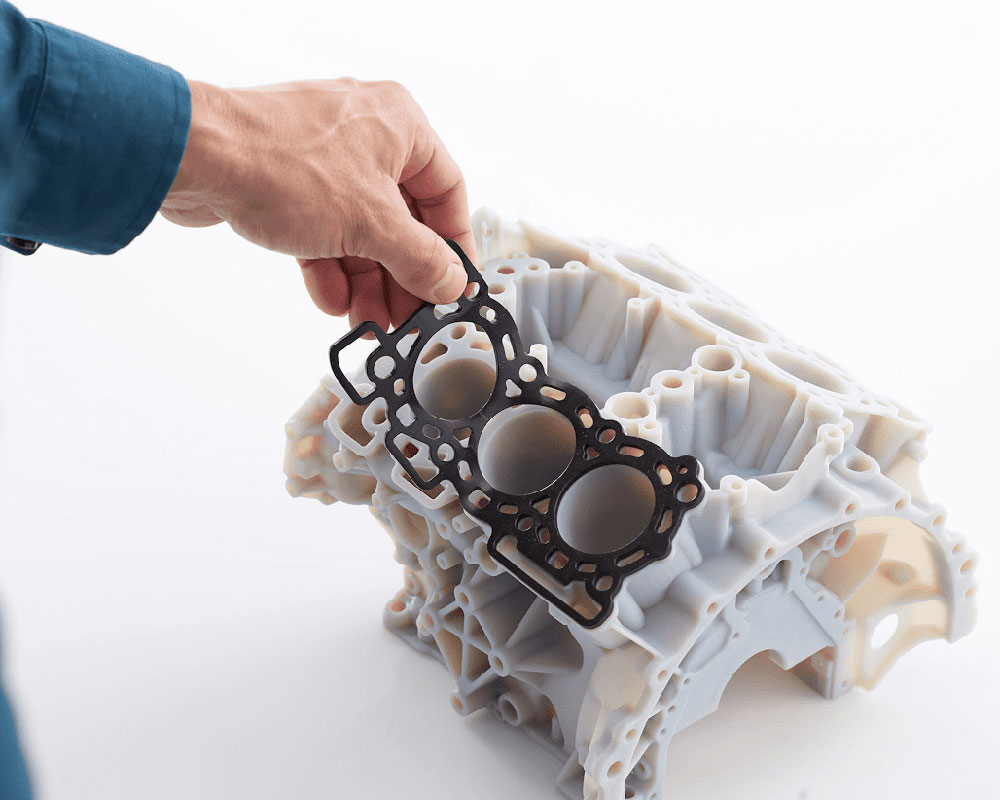

Our PolyJet materials enable us to produce flexible, tear-resistant products with our Agilus-30 PolyJet Photopolymer, as well as the option to request a soft, flexible 3D printing material called Tango. This substance excels when requirements include a non-slip surface. If you need a smoother prototype used for surgical models, we also offer a vibrant color 3D material option.

We now also have the ability to print parts in-house using the Stratasys Polyjet technology, including the materials below:

- Biocompatible (MED610)

- DraftGrey

- Rigur

- Tango

- VeroClear

- Vero Rigid Opaque

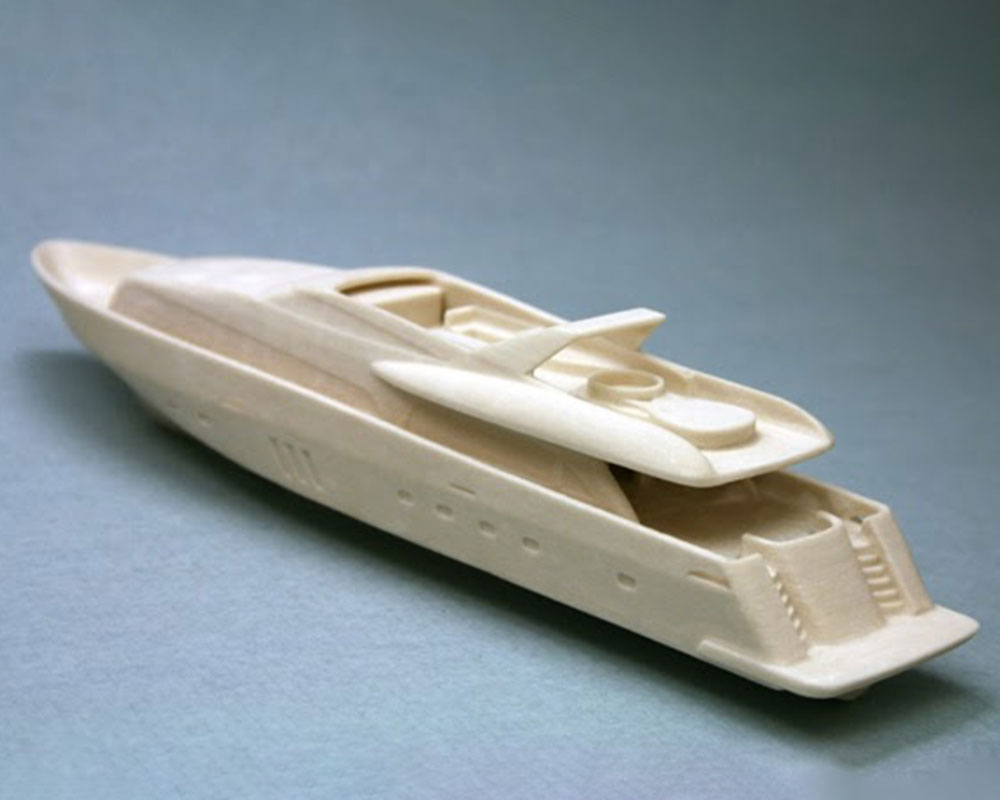

As well as offering materials suited for the medical industry, Lyseon’s Stereolithography material, Somos PerFORM, allows us to create products with excellent thermal and mechanical properties with a wide range of applications.

If you need high-quality, low-cost items, our Multi Jet Fusion materials offer a sturdy, yet affordable option. Our Ultrasint® TPU01, multi-purpose thermoplastic polyurethane provides shock absorption, energy return and flexibility. Our PA-12 Glass Beads will allow you to make use of excess materials.

For more information about 3D printing materials from the experts at Lýseon Additive Manufacturing, please contact us here or call us directly at 248.514.1829.